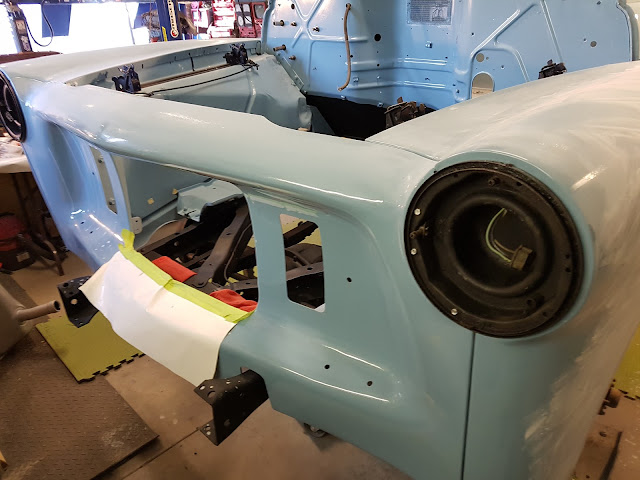

With the truck painted inside and out (and partially color sanded), it's finally time to tackle the re-assembly of all the bits and pieces. Although I'm still waiting on the rebuilt engine, re-rimmed wheels and tires and re-upholstered seat set, I can get to all those peripheral parts in the interior, a well as the lighting, electrical, door glass and chrome. This is the reward for all those hours welding, hammering, sanding and sanding...and sanding....

Every itme going back is prepped and coated in either POR15 Semi-gloss, or Eastwood's Chassis Black which is a very Gloss Black.

The vent glass frame was painted in chassis black. Very nice stuff it is.

The heater box, motor and central mix-box was tested and installed next.

Windhsheild wiper motor was installed next.

Unfortunately, the jar I had stored the leftover product in had a bit of an air-leak and - as I've talked at length in previous posts about the incredible hardening nature of this single stage urethane paint - you'll know that this generally means premature hardening and issues with long term usage...

Sure enough, screw drivers and ice picks would not penetrate the hardened upper most layer:

It looked like it was still liquid further down into the jar, so I drilled a 1/2" hole

into the top 1\2" hardened layer to get to the usable part below.

After a full coat it looked fantastic and will look 'show'

once hung in it's original location under the running board.